This blog is a special feature leading up to the 2021 Spring Meeting by one of our title Sponsors, Reid Middleton.

By: Chris Hartman, P.E., Director of Engineering at Port of Port Angeles and Wendell Johnson, AICP, PLS, Principal Planner at Reid Middleton, Inc.

RESILIENCE – the ability to recover from, or adjust to, the negative impacts of external (economic, environmental, and other) “shocks”.

Resilience is a major thread woven throughout the story of development of the Marine Trades Center by the Port of Port Angeles. As anyone who is familiar with the economic history of the Olympic Peninsula can attest, the last 50 years has seen significant impacts to the timber industry that have had profound implications for the local economy. This article will highlight the efforts of the Port of Port Angeles in developing a greater degree of economic resiliency of the Clallam County economy while at the same time building environmental resiliency into those development efforts.

Timber-related industries have dominated the Port Angeles waterfront for over a century. The Port of Port Angeles (“The Port”) realized that cleanup and redevelopment of the roughly 18-acre site of the former PenPly Mill could be a key element in their strategic plans to diversify the local economy. Over the years prior to the mill closing, the Port had experienced success in drawing boat and ship manufacturing and maintenance operations to properties to the west of the mill site. The Central Waterfront Master Plan completed in 2010 first identified the mill site as having great potential for a Marine Trades Center that would capitalize on the previous successes and diversify the marine trades industry.

Shortly after the mill closed, the Port worked diligently with the Washington State Department of Ecology to remove the more than 180,000 square feet of mill structures, investigate the site for soil contamination, and perform all necessary cleanup actions to make the property ready for redevelopment. The mill structure demolition was completed in 2013 followed by a site investigation and development of a contaminated soils cleanup action plan in 2014 and 2015. The site cleanup, which included removal of 54,000 tons of petroleum-contaminated soils, was begun in 2015 and completed the following year.

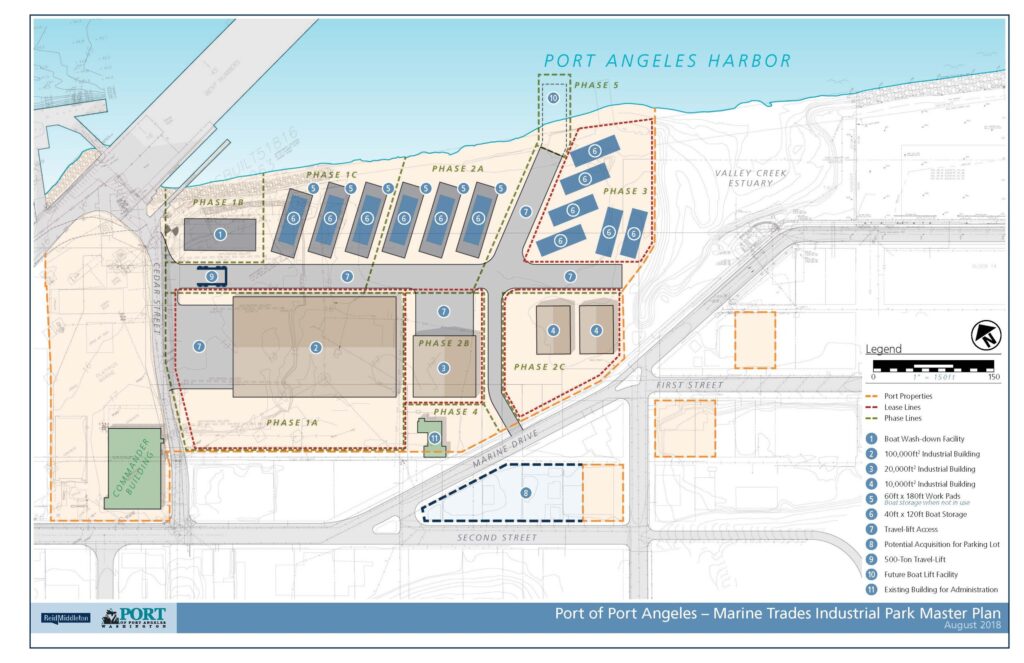

In 2016 the Port selected the Reid Middleton team to develop a master plan for the Marine Trades Center (at that time referred to as the Marine Trades Industrial Park). Reid Middleton served as the Prime Consultant, BST Associates provided economic analysis, Hart Crowser provided environmental and geotechnical services (a member of the previous cleanup team), Kennedy Jenks provided boat-wash facility consultation, and Northwest Territories provided local land survey support.

Working with the Port, the consultant team contacted local companies in the marine trades industry to provide input that would guide development of the master plan. The seven participants represented both the marine services and marine manufacturing sectors as well as the Makah Tribe. The findings of these in-person interviews were distilled into five distinct guiding elements for the master plan:

· A need for a boat/ship washing facility large enough to handle the largest of the ships being hauled out of the water by the 500-ton Travelift.

· Strong need for a large building that can be leased for short periods of time for boat and ship sand blasting, painting, welding, and other service and manufacturing activities.

· Work pads for boat and ship maintenance activities. The work pads need to provide basic utilities needed for the activities envisioned while also collecting and treating wash water and other by-products of maintenance activities.

· Space for buildings anywhere from 10,000 square feet to as large as 100,000 square feet to accommodate expansion plans of existing tenants and lure local area marine trade businesses presently operating elsewhere in the County.

· Space for boat storage (although recognized as a lower priority since the use does not produce many jobs in relation to the space required.)

These guiding elements were then translated into three development alternatives for the Marine Trades Center. After the alternatives were evaluated by Port Staff and reviewed by the Port Commission, a preferred alternative emerged (shown below).

The next step was to develop an Infrastructure Master Plan based on the preferred alternative above. With an eye to redundancy and resiliency, the primary power and water utilities serving the site were “looped” into existing systems in such a way that should a disruption occur in one part of either system, the service can still be provided from the other side of the loop. The Master Plan also provided a strategy for use of Low Impact Development practices to treat stormwater runoff before discharge into the bay.

The first implementation of the preferred master plan alternative began when the Port engaged Reid Middleton to design the boat wash facility identified as a valuable addition for many tenants at the site. With the help of team members BCE Engineers (mechanical engineers), Hart Crowser, ClearWater Services (water treatment specialists) and ProDims (cost estimating) construction documents were prepared for a 175-foot-long by 75-foot-wide wash pad, together with an 80-foot-long approach apron. The documents included a state-of-the-art wash water treatment system housed in a CONEX box that improved wash water quality to the point that it met City of Port Angeles standards for discharge into its public sewer system. The design included dedicated wheel paths for the 500-ton Travelift using thickened pavement sections to accommodate the significant point loads of the Travelift. The dedicated wheel path approach design saved money by allowing other portions of the wash pad slab to be less robust, yet strong enough to support expected heavy machinery use. The construction was completed late in 2018. The image below shows the new wash facility in operation.

With the new boat wash facility completed and operational, the Port examined other elements of the master plan might provide the best return on investment of limited construction dollars. It was during this investigation that the Port learned of the Economic Development Authority’s (EDA) Fiscal Year 2019 Disaster Supplemental Notice of funding Opportunity. At the urging of EDA, the Port prepared grant application documents in hopes of acquiring matching grants to fund construction of the entire master plan infrastructure. The application package included an Economic Impact Narrative prepared by BST Associates that made the following compelling arguments for award of the grant:

The Marine Trade Industrial Park project increases the economic resilience of Clallam County by:

•Providing the infrastructure needed to expand a critical cluster industry (ship/boat building and repair)

•Strengthening the economic base of existing employers to enable growth and,

•Attracting new employers to continue expansion in this successful industry that provides family wage jobs.

After review of the grant application, the EDA issued a tentative commitment to award, but requested that the Port secure required permits for a critical element of the infrastructure; a new stormwater outfall through which most of the runoff generated by the project will be discharged to the bay. With Hart Crowser, the Reid Middleton team was asked to assist the Port in obtaining permits for the new outfall.

A critical component of the current planning for the stormwater system and outfall is the pending update to the Washington Boatyard General NPDES Permit. With potential new stricter limits on discharges from boatyards, the Port will need to implement a robust system for the treatment of stormwater from the project site before it discharges through the new outfall. The resiliency of the new stormwater treatment system, including flexibility built into the system for future regulatory discharge limits is critical.

The Port continues to move forward on a resilience path for the site, creating economic opportunities and environmental improvements, while incorporating the flexibility to adjust to future shocks.